We also handle the excavation of underground water lines and sewer main lines.

#Copper tube bending how to#

#Copper tube bending Patch#

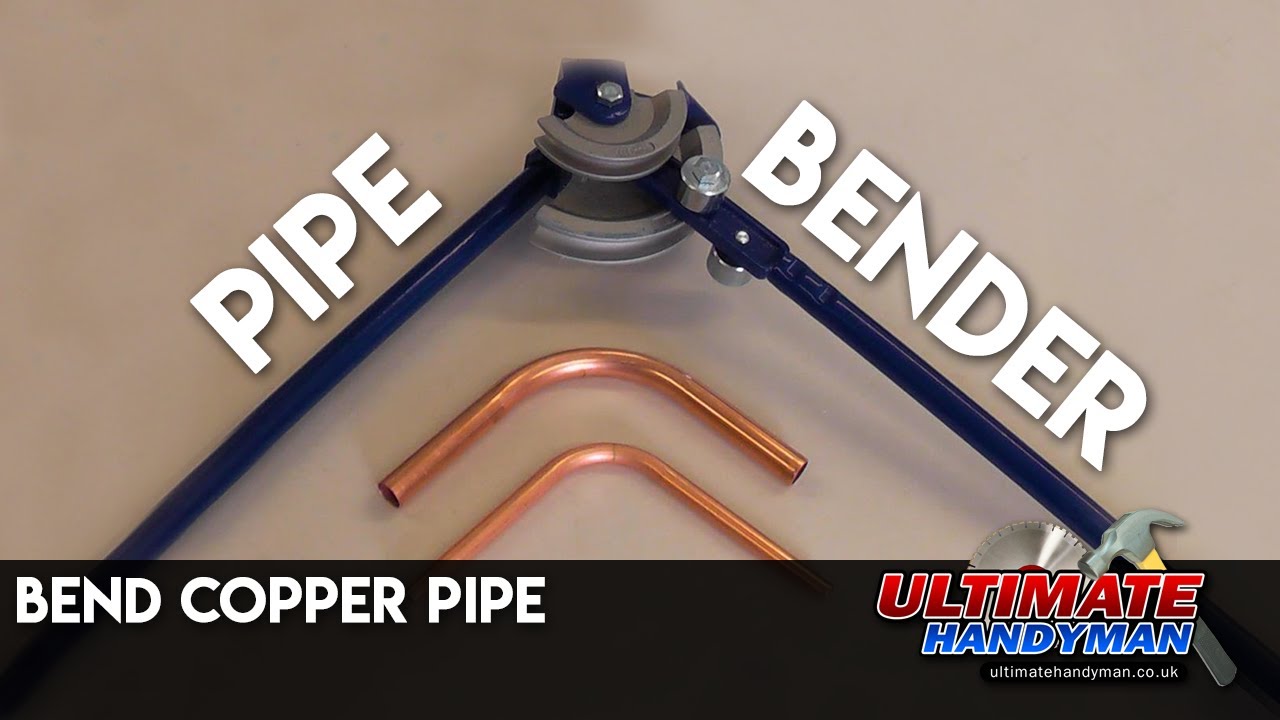

Our company is also one of the few vendors that offer post-bend threading and 45-degree flare ends for custom copper tubing.īecause we focus on creating custom copper tube components, our customers know that they’ll receive the highest quality products for their unique applications. Copper tube bend failure Copper tube bend failure irishal (Industrial) (OP) 7 Aug 06 11:27. We use specialized equipment and offer custom threading, end configurations, and other services to provide turnkey solutions for your copper tube bending project. Triad Products specializes in custom copper tube bending and copper tube fabrication for small to medium production runs ranging from 100 to 1000 pieces. We work with OEMs across a broad range of industries and provide specialized secondary operations including welding, flaring, and post-bend threading you can’t find elsewhere.Ĭustom Copper Tube Bending for Heating and Cooling Applications With our custom copper tube bending and copper tube fabrication capabilities, we can meet the needs of a wide range of applications and industries that use bent copper tube. Custom Copper Tube Bending for All Industries & Applications Each process is unique and provides different benefits, and the company performing the copper tube forming will determine which is best for your specific project.Ĭontact us to learn more about our customized copper tube forming services. Copper tube bending is accomplished using different equipment and methods such as rotary draw bending, roll bending, mandrel bending, and ram bending. Bending copper pipes requires some measurement and precision angle work, so don’t think you can hire a bender to get a perfect job. The excellent formability of copper makes it easy to bend, though caution must be taken to prevent crushing during the bending process.

Copper Tube Components & Copper Tube Fabrication Finished tubing is joined together using threads, flared ends, compression fittings, and soldering.

Custom copper tubing is also used to manufacture refrigeration and supply lines, and cooling components for lasers and laboratory testing equipment. Keep in mind, in almost every case, you will be connecting flexible. You’ll also need (1) a tubing cutter, (2) a coil-spring tubing bender, and (3) some emery cloth. These properties, along with its excellent corrosion resistance, makes copper tubing a preferred choice for residential and commercial plumbing applications. To prepare the tubing for your project, you’ll need about 15 minutes to bend and cut the tubing (for a relatively short run of pipe). Copper Tube Components & Copper Tube FabricationĬopper is a material that offers excellent thermal and electrical conductivity and tolerates extreme temperatures.

0 kommentar(er)

0 kommentar(er)